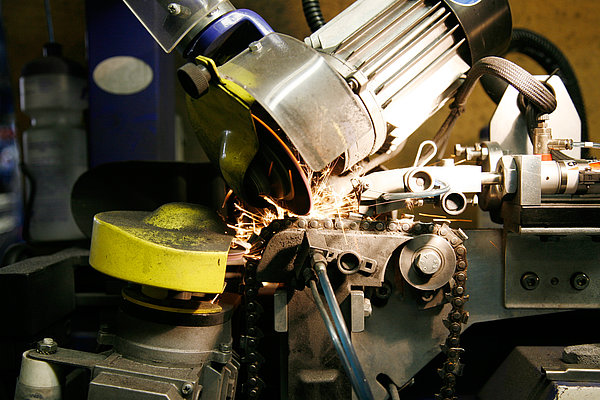

Automatic chain sharpener

The chain sharpener SA6 - The Franzen - sharpens automatically ...

... all types of saw chains such as:

- 1/4"; .325"; 3/8"; 3/8" picco to .404"

more precisely, consistently and quickly.

It also sharpens sawmill- and special chains such as:

- chipper chains with 15mm and 20mm pitch

- scratcher chains (also carbide tipped!)

- HOLTEC-Skipchains (also carbide tipped!)

- 3/4" chains

- Mafell ZSX chains

with additional attachments.

All the necessary movements (feed, pivoting, grinding, etc.) for a satisfying experience are accomplished by the Franzen SA6. There is no surveilance necessary at any point of the process. By a threefold scannerhead the machine detects right and/or left teeth. Should there be several right or left teeth in a row, the machine will still operate correctly (no interruption of the process). In case a tooth is missing, the machine automatically shuts down to avoid any damage to the chain. Always the last transported tooth will be sharpened before shutdown.

An example you might know from your daily work

Your shop is at the brink of its capacity limit during every years gardening- and forestry season. But you cannot just focus on repairing equipment for example, as customers will still step by your store, no matter how much work you have. Let´s take one customer who wants three chain saw chains sharpened. As you have a ton of work to finish you kindly ask your customer to step by the next day to pick up the chains. The customers does not really like that idea and wants his chains done right away. We all know that the "customer is King", so you set your work aside and sharpen the chains, despite the fact that this will only cost you time.

Of course the chains are in bad shape and the rakers (depth gauge) need some treatment too, so you will have to run the chains at least twice each, which means 8-10 minutes per chain easily. So overall, you will loose roughly 30 minutes for three chains.

The solution to such stressfull situations is right around the corner. Just use the Franzen automatic chain sharpener to satisfy your customers and make them come back every time.

Technical Data:

| chains: | 1/4" to .404 (15 mm & 20 mm with optional attachments) | |

| angle: | 0° - 5° - 10° - 15° - 20° - 25° - 30° - 35° - 40° - 45° - 50° | |

| link-thickness: | 1,1 mm to 2,0 mm (3,0 mm with optional attachments) | |

| power supply: | 220 V / 240 V, 50 Hz (all other voltages possible) | |

| air requirements: | 6 Bar / R 1/4" quick release | |

| abrasive wheels: | tooth: 150 x 3,2/ 3,8/ 4,5 / 6,0 mm | |

| (Franzen-grinding wheels) | rakers: 120 x 7 / 120 x 9 mm | |

| for carbide tipped chains: diamondwheel 145 x 3,2 / 4,0 mm | ||

| dimensions: | 25.6" x 25.6" x 74.8" (depth x width x height) | |

| weight: | ca. 200 kg (440 lbs) |